DIY Single Sided PCB

Making your own Printed Circuit Boards (PCBs) at home can be an affordable solution when going from a project on the breadboard to a final state. I base my work on the pioneering work done by Tom Gootee. http://fullnet.com/~tomg/gooteepc.htm

By the way, do not get ticked off at me if your results are not fabulous. What you do with this information is up to you.

Background information:

When I discovered Tom's webpage using a Google search on PCB fabrication at home, I quickly became intimate with every detail of what was published at Tom's web site. I originally used the Staples photo paper he mentioned, but it has changed and no longer gives good results (in fact, your toner transfers will fail nearly every time and a nasty plastic residue will stick to your copper blank).

My specific background information is as follows:

· I bought my "oldish" GBC Creative laminator at a local used item thrift store (Goodwill for the curious) for under $15. It is mechanical only and controls the temperature of the rollers using a mechanical un-settable thermostat.

· I buy my etchant components; peroxide, muriatic acid and bulk acetone from the local druggist/pharmacy and/or the home supply store (Lowes/Home Depot).

· The transfer paper I use now use is still from Staples, but it is the heavyweight 32lb laser glossy paper, listed as part # 633215. It is about $10 for 500 sheets.

· I only recommend using a laminator for transferring the image to the copper, as my hand iron based work was sub-standard and just never as good as the laminator solution.

Copper Clad Board:

I usually use "MG Chemicals" PCB material product numbers #503 or #506 as these are available from my local brick and mortar electronics retailer.

http://www.mgchemicals.ca/products/600.html

At this point, you should know the dimensions of your PCB artwork and should cut the PCB blank to the appropriate size before continuing. I use a 8" mini shear/brake from the Grizzly catalog to cut my PCB material. Catalog # T23109 ITEM: 8" Mini Shear-Brake

Note: 1/16th"

thickness is about the maximum that my laminator will

accept.

Preparing the PC Board surface

Figure 1

Usually the purchased copper blank should look decent and not corroded, see Figure 1, but it still needs cleaning. I start with a kitchen cleanser that is based on a scouring powder (like AJAX). If I don't use the kitchen cleanser method, I lightly sand the board using a very fine grit sandpaper and water (wetsanding). This second method would be the one I use if the board has some corrosion or excess oxidization. In the end, this mild scratching of the copper surface will give the toner something to grab. As a final prep before the next step, put on rubber gloves and clean the board with acetone to remove all traces of grease and oils. Rub any residue off the board with a lint free cloth. Your board should look like Figure 2.

Figure 2

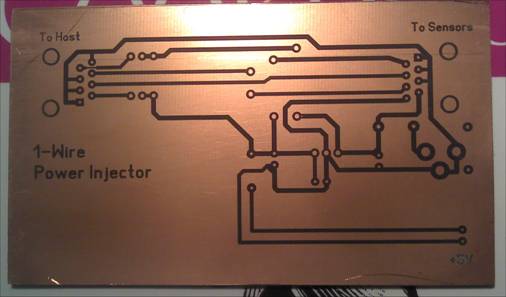

Transferring the artwork

While discussions about what is used to create the artwork can be as much fun as discussing favorite text editors, the end result is the same... you need a negative image of your design printed onto the glossy laser paper. The PCB software I use knows how to print the PCB design so no fancy steps are required. Use the darkest and highest resolution setting your laser printer has. Check to make sure that coverage toner is good. Some laser printers have an automatic toner saving mode and on the highest settings may not give best results. Perform some test prints and select the best settings based on your actual printer.

I have seen some web based examples where the toner is printed twice on the same piece of paper to get an extra thick layer. My results with this technique are not what I expected since my printer is unable to get the alignment exactly right each time.

This next step is important! Turn on your laminator at least 20 minutes before you start using it or otherwise it will be too cold.

Using painter's masking tape, tape 2 ends of your printed artwork to the copper side of the blank. Make sure of the following before you do this:

1) Using an air duster, blow clear all loose dust from the copper and paper.

2) Make sure your paper is lying flat on the board, no binding or curling.

When ready, pass the board with artwork through the

laminator 6-8 times with the shortest possible pause between passes.

Removing the paper backing

This is where choosing the right paper comes in handy. Drop the PC board in a container of slightly warm water and wait 60 seconds. The paper should be buckling almost at once and just dying to come off the copper. I usually slice through the edge of the painters tape to make removal a bit easier. You should have no trouble getting it all off at once or at least in very large pieces. Using your thumb, lightly rub any stubborn spots or light rub with a small plastic brush. In the image below there is only 1 minor pinhole.

Preparing the etchant

This next bit is easy… but you need to protect your skin and nose. Your lungs do not like muriatic acid fumes (aka hydrochloric acid solution).

Locate a small plastic container to hold your etchant bath. I use OLD Tupperware items from the thrift store. Using a smaller plastic measuring container add 2 equal measurements of peroxide to the container for your etchant bath then add 1 measurement of ACID. Again, avoid breathing any acid vapors… you can try it if you like but do not say I did not warn you. You will very likely have a violent involuntary cough if you breathe the fumes. I work outdoors for this step.

The stronger the solution (acid to peroxide ratio) the faster the etch time but be aware that the process is also somewhat exothermic. The etching process is assisted by some slight agitation. I use a piece of paper towel stuffed into 1" diameter tube to lightly wipe the copper surface while etching. The board I'm currently working on etched completely in about 5 minutes. Rinse with water.

Once the etching starts, your solution should start turning a light green color.

Remove the Etch Resist

This next step is rather simple but it might take some extra time to get it clean. It really depends on how your toner behaves when exposed to the solvent. Since I have acetone handy, I use it. It reacts quickly with the toner, dissolving it… but it quickly makes a black mess. In my case, I usually need to resort to some wet sanding to remove the final bits of toner from the fiberglass.

The sandpaper cleaning is a good thing, since the manufacturer recommends it if you are going to do the next optional step.

Tinning

There are all sorts of messy tinning options available, but most require immersion in costly liquids that have a limited shelf life. I chose to use Ed Nisley's method of rubbing the board with COOL-AMP (silver plating powder). I bought the 8oz package and at the rate that I use it, I will still have plenty in 10-20 years. (See Ed's blog at http://softsolder.com/)

Where to get the powder: http://www.cool-amp.com/

Yes, I know that Silver plating using a powder is not quite the same as "tinning" but I will say that 1) Silver is much more conductive than copper and 2) it works exceptionally well when soldering. Overtime, you do get a little tarnish… but that really is not much different from what happens with exposed copper oxidizing.

All that is left is to drill and populate the board. I did purchase some carbide PCB drills from EBAY and although these bits are very, very fragile, the results are superb.

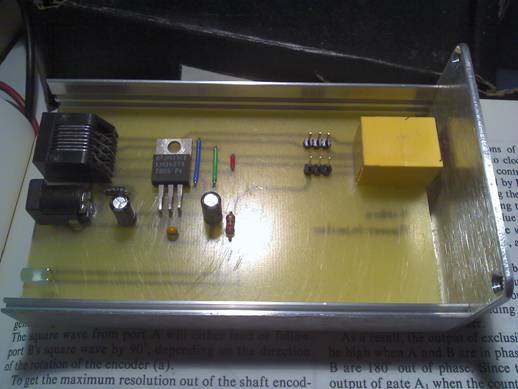

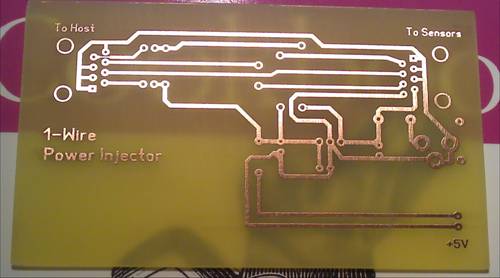

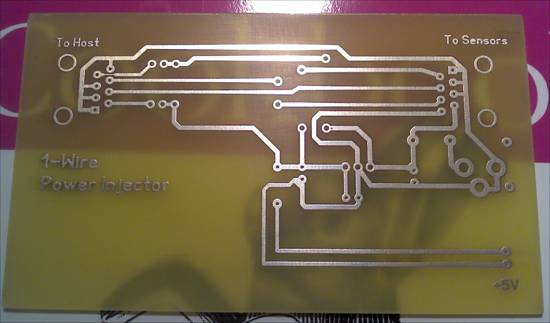

Finished Board: